Business Area

Smart Logistics

aim Systems is providing logistics automation solutions for high tech and general manufacturing.

A logistics control system that optimizes travel time by managing transport orders for logistics equipment

A logistics control system that optimizes travel time by managing transport orders for logistics equipment

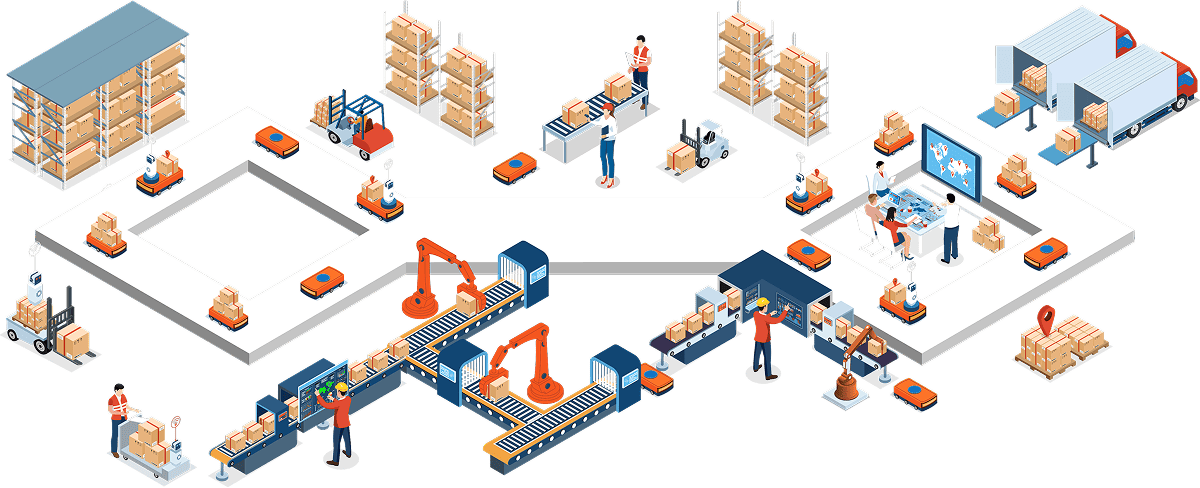

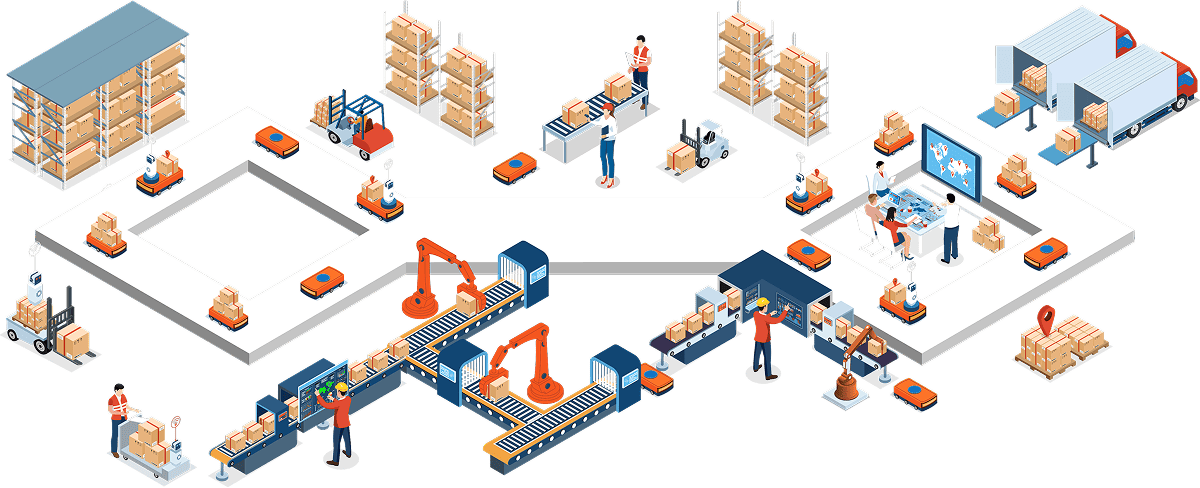

We integrate and manage the automation of logistics facilities in factories, including stockers, OHTs, and AGVs, as well as transportation, inventory, warehousing, materials management, and packaging, while implementing a smart logistics system that incorporates AI, IoT, and robotics.

Warehouse Automation

Implementing smart warehouse automation is essential for increasing warehouse efficiency, reducing time and costs, and providing better customer service.Build smart warehouse automation by integrating automated logistics facility control and a warehouse management system.

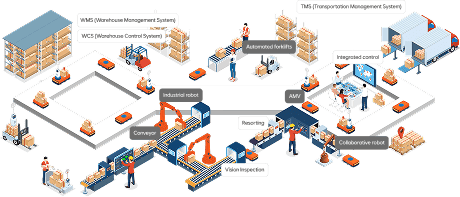

Configuration Diagram

Warehouse Automation Implementation Details

Unloading items

Receiving

Sorting

Inventory

Loading items

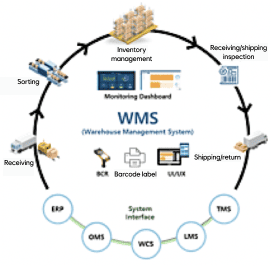

WMS (Warehouse Management System)

WCS (Warehouse Control System)

TMS (Transportation Management System)

Integrated control

Resorting

Vision Inspection

Conveyor

Industrial robot

Automated forklifts

AMV

Collaborative robot

WMS (Warehouse Management System)

WCS (Warehouse Control System)

TMS (Transportation Management System)

Integrated control

Resorting

Vision Inspection

Conveyor

Industrial robot

Automated forklifts

AMV

Collaborative robot

WMS: Warehouse Management System

WCS: Warehouse Control System

Enterprise System

ERP

OMS

TMS

LMS

Automatic Warehouse Management

WMS(Warehouse Management System)

Integrated Logistics Control

Automated Logistics Control

WCS(Warehouse Control System)

SCS (Stacker Control System)

CCS (Conveyer Control System)

ACS (AMR Control System)

Data Collection

Automated Logistics Equipment

Stacker

Crane

Conveyer

Sorter Belt Conveyer

Lifter

AMR/AGV

Automated forklifts

Automated forklifts

Collaborative robots

loT

- loT Temperature Sensor

- IoT Humidity Sensor

- CCTV NVR

- ID Reader

Supply Solutions

WMS

- Semiconductor-specific processes

- Workflow-based flexible operation scenarios

- Addressing diverse manufacturing needs

- Optimization by manufacturing type

- Flexible adoption support and customization

- SEMI standards-based integration and extensions

WCS

- Various communication protocols provided: SECS/GEM, OPC, PLC UA

- Facility scenarios provided based on equipment type: standalone, combined, and inline

- Real-time monitoring and control

- Real-time processing of large amounts of data

ACS

- Integrated control of multiple AMHS devices

- Field-based modeling and real-time monitoring

- Intelligent route optimization and real-time route optimization

- Prevention of production bottlenecks and optimization of materials movement

CCS

- RMS (Recipe Management System)

- rSPC (Real-Time Statistical Process Control)

- FDC (Fault Detection & Classification)

- FMB (Factory Monitoring Board)

- Report

SCS

- RMS (Recipe Management System)

- rSPC (Real-Time Statistical Process Control)

- FDC (Fault Detection & Classification)

- FMB (Factory Monitoring Board)

- Report

Smart Logistics

Reference

If you’d like to learn more about actual implementation examples, click Contact Us.

Customer & Partner

고객 및 파트너사와 기술 협력 모델로 Digitalization Smart Factory 를 선도합니다.