Business Area

Smart Factory

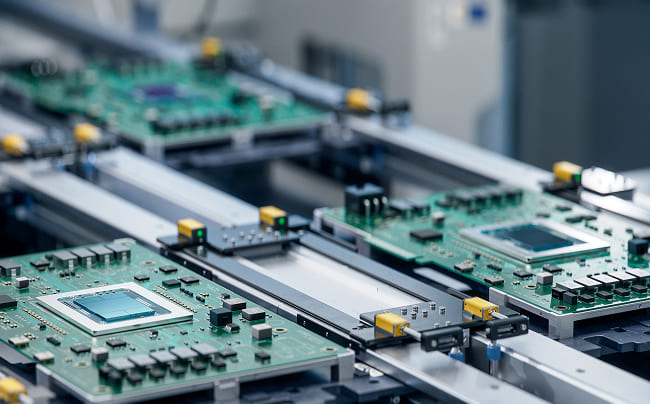

As a first-generation factory automation pioneer, aim Systems leads

the market by providing automation solutions and engineering services based

on our advanced technology and expertise.

the market by providing automation solutions and engineering services based

on our advanced technology and expertise.

Leveraging core technologies in the semiconductor and display fields, we have expanded our business into smart factories, logistics, and airport infrastructure, while building a new ecosystem with a cloud-based manufacturing integration platform.

Furthermore, we are advancing toward creating future value in industrial automation through continuous innovation and integration.

Automotive,

electronic parts/ assembly

electronic parts/ assembly

Our solution helps manage the entire process of automobile assembly and automotive parts production in real time.We implement a high-quality production system by detecting and resolving quality risks early through integrated monitoring of production processes, material control, product tracking, and equipment maintenance.

Implementation Details

System Implementation Highlights

Key Details

Expectations

Key Details

Expectations

- Process modeling tailored to different assembly types

- Real-time production performance monitoring

- Application of various latest devices optimized for field conditions (tablets, mobile PDAs, kiosks)

- AGV-based Automated Transport

- Increased production efficiency through highly scalable master data modeling

- Improved production management through advanced systems

- Increased convenience and productivity in the field

- Enhanced DT level through increased system reliability

- Cassette/Reticle management

Key Details

Expectations

- BOM master data revision control

- LOT traceability linked to material input records

- Support for material flow and inventory management features (integrated with ERP)

- Quality improvement through prevention of incorrect inputs

- Reduction in defect rates through improved production management

- Improvement in quality management levels

Key Details

Expectations

- Process exception handling operations

- Handling of RMA process, rework, and repair processes

- Anomaly detection and analysis features

- Cost savings from reduced rework

- Increase in quality products due to the repair process

- Inventory cost reduction

Key Details

Expectations

- ERP-connected work plan creation and performance processing

- Production monitoring for delivery management

- Planning / performance management dashboards

- Real-time tracking of actual performance against the plan

- Production lead time prediction and potential reduction

Supply Solutions

MES

- Semiconductor-specific processes

- Workflow-based flexible operation scenarios

- Addressing diverse manufacturing needs Optimization by manufacturing type

- Flexible adoption support and customization

- SEMI standards-based integration and extensions

EAS

- Various communication protocols provided: SECS/GEM, OPC, PLC UA

- Facility scenarios provided based on equipment type: standalone, combined, and inline

- Real-time monitoring and control

- Real-time processing of large amounts of data

Report

- Integrated control of multiple AMHS devices

- Field-based modeling and real-time monitoring

- Intelligent route optimization and real-time route optimization

- Prevention of production bottlenecks and optimization of materials movement

rSPC

- RMS (Recipe Management System)

- rSPC (Real-Time Statistical Process Control)

- FDC (Fault Detection & Classification)

- FMB (Factory Monitoring Board)

- Report

Smart Factory

Reference

LX SEMICON

구축기간 :

2023.07.02 ~ 2024.03.08

상세 스펙

- Project

- MES Implementation Project

Site :

Site :

Solutions :

MES, EAS, SPC

- Solutions

- MES, EAS, SPC

Tovis

구축기간 :

2019/06 ~ 2019/12, 2018/11 ~ 2022/04

상세 스펙

- Project

- Tovis MES(Seocheon, Dalian)

Site :

Site :

Solutions :

MES, EAS, Report

- Solutions

- MES, EAS, Report

OE solutions

구축기간 :

2020/06 ~ 2020/12

상세 스펙

- Project

- MES Smart Factory Implementation and Advancement Project

Site :

Site :

Solutions :

MES

- Solutions

- MES

If you’d like to learn more about actual implementation examples, click Contact Us.

Customer & Partner

고객 및 파트너사와 기술 협력 모델로 Digitalization Smart Factory 를 선도합니다.